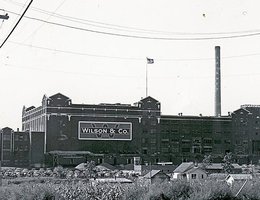

Traditional packing houses were multi-story buildings where livestock were driven up a long ramp to the top floor. They would also slaughter different species in the same building, which required different departments. Then they moved the carcass from the killing room to the chiller and into a railcar.

They also saved money by going directly to the rancher or farmer to buy cattle. This took the stockyards out of the deals. And with large trucks, they transported their cattle straight from the feedlot to the processing plant which saved even more money.

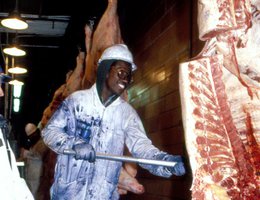

IBP also changed the industry by developing boxed beef. Transporting carcasses to butchers required more time, space, and money. It meant that the slaughterhouse shipped a lot of waste material, and carcasses did not fit easily into the rectangular spaces of refrigerated trucks and rail cars. By cutting the carcasses into smaller pieces that fit nicely into boxes, they were able to pack much more beef into a truck. This greatly reduced the cost for transportation. Because they were doing more of the processing at their plant, the beef required less skilled labor at the meat counter.

In 1967, IBP opened a new, highly automated and immense plant at Dakota City, Nebraska, a small town just across the Missouri River from Sioux City, Iowa, another major meat-producing city. This became their flagship plant and headquarters.

IBP’s innovations seriously threatened traditional meatpacking jobs, and national unions knew that. Soon, the Dakota City plant became the location of dramatic, sometimes violent, strikes.

By 1973, the busy stockyards and packing plants of twenty years earlier were almost gone. Nebraska was still a beef state, but the way beef was fed, slaughtered, and sold had completely changed in just a quarter of a century.